Rotating equipment condition monitoring

Why should we use predictive maintenance techniques?

|

On average, eight out of ten different machines or their elements do not obey the logic of "gradual wear" (depreciation). Equipment can fail this year or in 10 years with equal probability. It is caused by a combination of different, always fluctuating conditions like manufacturing quality, installation quality, operating conditions, maintenance practices, etc. Unplanned breakdown repairs can cost you up to 10 times more and take up to 5 times longer to fix than planned repairs. Such breakdowns can also cause significant downtime losses, potentially amounting to thousands of euros per hour caused by slowed or halted production processes, which is impossible to recover. Fortunately, most equipment failures develop gradually, allowing for the possibility of detecting potential issues early on through regular monitoring. This proactive approach enables you to address potential problems before they escalate into major issues. The "health" of rotating equipment can be measured by key parameters such as vibrations, temperature, current consumption, and oil quality.

|

In 2023, SIA Industry Service Partner became a distribution partner of ERBESSD INSTRUMENTS to offer its customers modern and effective equipment condition monitoring products and solutions. Why ERBESSD INSTRUMENTS? This manufacturer provides affordable, open-access machinery diagnostic solutions that are very easy to deploy. That is why we in Industry Service Partner are currently able to provide the following:

|

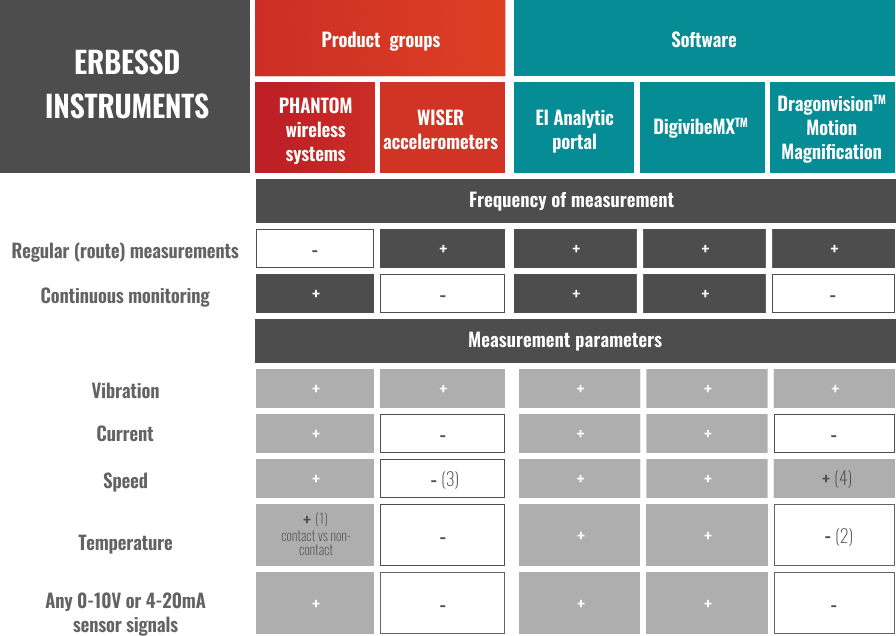

ERBESSD INSTRUMENTS diagnostic products overview table

| 1) The vibration transmitters have internal sensor for temperature control measurement, as well as contact and non-contact sensors specially designed for temperature measurements 2) Using the time lapse photo or video functionality of the camera, it is possible to record changes in the geometry of the equipment caused by thermal expansion or contraction processes |

3) In addition, it is possible to purchase an external optical phase sensor that can be connected to WiSER 3x and 1x sensors (except WiSER mini, where this is not possible) 4) Rotation speed can be indirectly determined by analyzing the recorded video |